POLISHING

Polishing is a high-stream filtering process where suspended solids and BOD are removed from wastewater. Polishing removes remaining suspended solids and BOD that may be left after secondary effluent treatment. Polishing usually is the end phase in wastewater treatment process to make water more hygienic and environmentally safe for discharge into receiving waters.

During polishing process, wastewater passes through a cascade of fine high-stream sand, charcoal, fabric and/or carbon filters that gradually reduces particle size in the effluents to 10 microns (0,001 μm). Filters cause the waste particles from water to attach to the filter media thus making the water free of such particles.

The goal of wastewater polishing is to create a system which produces water that is ready for release in environment. Technology of wastewater polishing include various filtering and and automatic air-water backwashing solutions. Backwashing (also known as CIP - cleaning in place) is crucial to prevent the filters from clogging. Incorrect backwashing may decrease filters’ life significantly and result in extra maintenance costs.

For wastewater polishing, FlotLife delivers following equipment and services:

- high-stream sand media filters for micro-filtration (particle size >0,2 μm)

- membrane filters for ultra-filtration (particle size >0,1 μm)

- membrane filters for nano-filtration (particle size >0,01 μm)

- semipermeable membrane filters for reverse osmosis (particle size >0,001 μm)

- installation, training and support

- Skid mounted design

- Pre-piped

- Pre-wired

- Compact design for small footprint

- Factory tested

- Stand alone operation

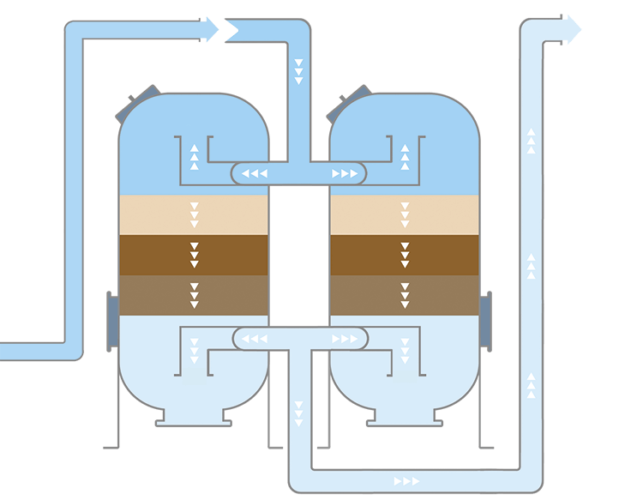

Filter SF-F are ideally suited for use in water re-use applications, water pretreatment applications or in wastewater clean up (polishing) applications after DAF systems. SF-F filter is designed as a twin plant with two parallel operating pressure filter tanks.

The construction of the plant ensures a doubling of the flow capacity by return flush in proportion to the filtering velocity. Backwashes of filter media beds sequentially, one at a time, using same source filtered flow from the other vessels, source backwash design permits the filtration system to continue filtering during backwash cycles.

Trough the use of automatically controlled backwashing and air-water mixture the filter will operate "on line" for extended periods of time prior to the short backwashing cycle, Automatic filter operation is monitored on elapsed time, as well as pressure differential. When the controller "calls" for a backwash as a result of pressure differential or elapsed time, the backwashing function utilizes a portion of the clean filtered water with air mixture produced by the working filter.