Wastewater from fish processing operations has very high organic content resulted from the presence of blood, tissue, and dissolved protein which means high levels of BOD and FOG, as well as high content of nitrogen and phosphorus. In case of fish processing, the degree of the contamination depends on the particular operation - it can be small (for example, washing operations), mild (for example, fish filleting), or heavy (for example, blood water drained from fish storage tanks). Fish processing requires large amounts of water, and the treated wastewater must be drained into the municipal sewage system or discharged into receiving waters (river, lake or sea) without any surcharges and in compliance with ecological sustainability requirements.

The fish processing industry consists primarily of plants located near industry and population hubs, therefore decentralized water treatment is the most economically justified solution because it allows to have full control over the entire process of wastewater treatment in order to make wastewater dischargeable into municipal sewers or receiving waters.

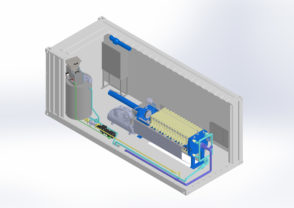

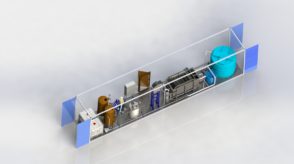

The wastewater treatment system can be delivered as a pre-assembled containerized plant or it can be assembled and installed in the factory premises.

FlotLife supplies fish processing plants with equipment and technology for full wastewater treatment process flow and customizes it to specific requirements of the customer. The system is fully automated for remote monitoring and control via a desktop computer or a mobile device.

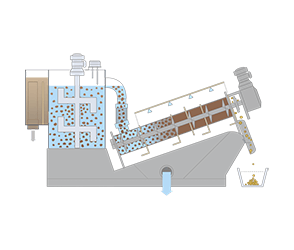

Although specifics may vary depending on many factors (e.g. water characteristics, production type, factory size etc.), the general process flow for fish processing wastewater treatment is following:

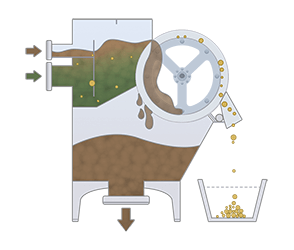

- Wastewater from fish processing contains a very wide buffet of solid waste that are removed by a rotary screen filter drum.

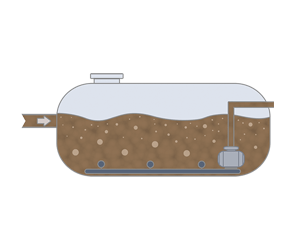

- Pre-treated wastewater is collected in a balance tank for intermediate storage to equalize its flow and freight.

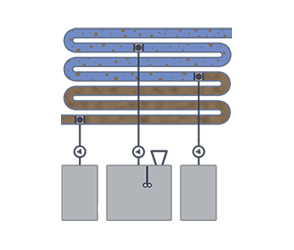

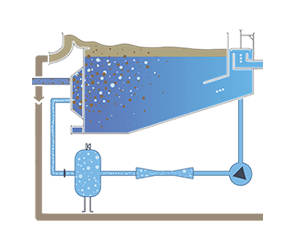

- The balanced flow is forwarded through a flocculation pipe where it is chemically conditioned (coagulated, flocculated and/or neutralized) and then pumped to dissolved air flotation (DAF) facility.

- DAF further clarifies wastewater by the removal of suspended matter through atmospheric pressure. After DAF, the treated effluent can be drained into municipal sewing system.

- The DAF effluent still contains COD and BOD freight which must pass biological treatment before being released to environment. Biologically treated effluent is of outstanding quality and can be directly discharged into receiving waters (river, lake, sea) or recycled as process water.

- Activated waste sludge from all stages where it is formed is collected, blended and fed to the sludge dewatering press where the excess liquid is separated from the thickened waste. The dewatered sludge can be used for biogas production.

The company "Irbe Fish" specializes in the production of high-quality canned fish. For production, "Irbe Fish" uses only cooled fresh and frozen fish of a particularly high quality. Company produces the canned fish from natural products of the Baltic Sea - sprats, Baltic herring, smelt, cod and flounder, as well as from the Atlantic - mackerel, sardine, herring and pilchard. Canned products include fish in oil, smoked fish in oil, fish in its own juice or with oil garnish, fish in tomato sauce. For its complete wastewater treatment system, "Irbe Fish" is running a containerized wastewater treatment plant supplied by FlotLife.

- DISCHARGESea

- FLOW200 m3/day; 10 m3/h

| Inlet, mg/l | Outlet, mg/l | |

| TSS | >1800 | >3 |

| P | 5–20 | 0,1 |

| COD | 2600–3200 | 18 |

| BOD | 1690–2600 | 5 |