DISSOLVED AIR FLOTATION

Dissolved air flotation (also known as DAF) clarifies wastewater by removal of remaining fat, oil and grease (also known as FOG) from effluent which has already passed several primary treatment phases.

Sludge management usually has two main challenges:

1) where to put the sludge;

2) how to reduce sludge disposal costs.

FlotLife offers a fast-track technology solution to both of these problems. FDS is an innovative multi-disc screw press manufactured by FlotLife for dewatering all types of sludge. FDS reduces the weight and volume of sludge by dividing the sludge into liquid and solid components. As a result, the amount of sludge can be reduced up to 7 times.

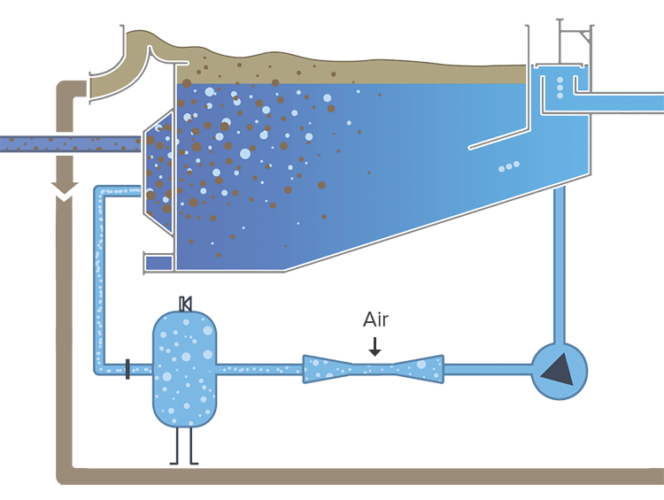

Wastewater is pumped into a flotation tank or basin and hit with dissolved air causing microscopic bubbles adhere to suspended solids causing them lift to the surface of the water where it may then be removed by a skimming device and drained toward a sludge discharge tank. Not-floating solids sink to the bottom of the DAF tank from where they are discharged by an automatically controlled pneumatic drain valve.

The goal of dissolved air flotation is to create a system which successfully treats a wide range of suspended solids at a high rate of solids removal. Technology of dissolved air flotation includes a range of components like flotation tank (flotator), skimmer, feed distribution well, and back pressure pump, valve, and saturation (the bubbles generation) system.

For dissolved air flotation, FlotLife supplies full set of technological equipment along with system installation, training and support services.

- High performance solid removal rates

- Highly effective, non-blocking dissolved air system

- Compact and space-saving structure

- Skid mounted design

- Easy to operate with minimal maintenance

- Optimum use of coagulants and flocculants

- Cost-effective

- Energy-optimized saturation system

- Industrial process water

- Industrial process water

- Drinking water plants

- Alage removal

- Slaughterhouses

- Meat processing and packaging

- Fish processing

- Dairies

- Food processing

- Tank truck tank washing

- Rendering plant processing

- Oil and fat refneries

- Petrochemical industry

- Metal processing

- Chemical industry

- Metal processing

- Waste management

- Margarine production

- Bakeries

- Car wash

- Textile industry

- Cosmetics industries

- Industrial kitchens

- HPDE

- Stainless steel: AISI 316, AISI 304

- Pressurization system

- Flocculation pipe

- Pump

- Adjustable effluent outlet

- PP tank or AISI 304 SS or AISI 316 SS construction

- AISI 304 structural support legs

- Infuent diffuser

- Effluent chamber

- Recycle saturation system

- Surface drag skimmer

- Lifting lugs

- Factory tested

- Seamlessly integrates other FlotLife wastewater products

- Stand alone operation

- Standard units can be manufactured for flows from 2 to 500 m3/h, in a single above grade

- Chemical pretreatment systems

- Duplex systems for redundancy

- Effluent sampling

- Explosion – proof design

- Flash mix/flocculation pipe

- Instrumentation and controls

- Removable covers with gaskets

- Container solutions

- Potable water design

- SCADA monitoring system

- Pilot size units for on-site testing

- Sludge handling and dewatering